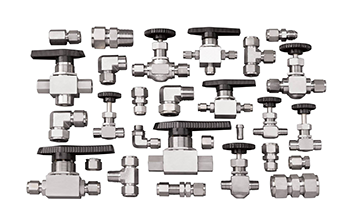

In the dynamic world of PVF, choosing the right fitting is crucial for maintaining system reliability, efficiency, and safety. Instrumentation tube fittings, also referred to as compression tube fittings, provide leak-proof, torque-free seals.

Two of the most popular types of tube fittings are single ferrule and double ferrule. In this blog, we compare single ferrule and double ferrule designs, looking at their features, benefits, applications, and more.

Instrumentation tube fittings are essential components designed to provide secure and reliable connections in various piping systems. Tube fittings connect tubing sections within hydraulic, pneumatic, and fluid delivery systems. They ensure a tight and secure fit that can handle high pressure and corrosive substances without leaking and maintaining system integrity. Instrumentation tube fittings contain three components: nut, body, and ferrule (single or double).

EXPLORE MERIT'S TUBE FITTING OFFERING

A single ferrule instrumentation tube fitting consists of a nut, a body, and a single ferrule. The single ferrule acts as the primary sealing element. The nut tightens to compress the ferrule against the tubing, creating a leak-tight seal.

The single ferrule design allows for quick and easy assembly. These fittings are ideal for applications where quick installation, easy maintenance, and cost-effectiveness are top priorities.

Some key benefits of the single ferrule design include:

Single ferrule tube fittings are typically made from corrosion-resistant materials such as stainless steel or brass. They are designed to provide reliable and easy-to-use connections in a variety of settings. The single ferrule design is often used in commercial and light industrial settings where efficiency and value are important, such as in water and gas applications, light hydraulic systems, and pneumatic systems.

ORDER SINGLE FERRULE TUBE FITTINGS

Similar to single ferrule fittings, double ferrule instrumentation tube fittings consist of a nut and a body. However, this type of fitting has two ferrules instead of one - a front ferrule and a back ferrule. Rather than using a single ferrule fitting to seal and lock the fitting into place, the double ferrule design distributes the two functions amongst the front and the back ferrule.

The double ferrule design, the most common instrumentation style, enhances the fitting's ability to contain high pressure and vibrations. This makes it more robust against mechanical shock and thermal fluctuations.

Some key benefits of the double ferrule design include:

When it comes to critical systems demanding the highest level of security and leak-proofing, double ferrule tube fittings are unmatched. Made from robust materials such as stainless steel or brass, double ferrule tube fittings are designed to withstand harsh and high-risk environments. These tube fittings are ideal for applications in chemical processing, oil and gas, and aerospace industries.

The double ferrule design enhances sealing capabilities, significantly reducing the risk of leakage even under high pressure and vibrations. Additionally, their resistance to wear and tear makes them suitable for demanding applications.

ORDER DOUBLE FERRULE TUBE FITTINGS

Choosing the right type of tube fitting depends largely on what applications require for safety, durability, and cost. By understanding the specific benefits and applications of single ferrule and double ferrule fittings, wholesale distributors can make better informed decisions that align with project requirements and budgetary considerations. Whether you need fittings that offer simplicity and cost-effectiveness for less demanding environments, or robust, leak-proof solutions for critical applications, our extensive selection caters to every need.

Interested in learning more about instrumentation tube fittings? Our team is ready to provide you with personalized solutions, ensuring you select the fittings that not only meet but exceed your inventory needs and your customers' piping requirements. Explore our comprehensive range and discover how our product can enhance your operations. Join our family of professionals who trust Merit Brass for high quality pipe fittings and exceptional service.

Author: Hedy Hemlick, Merit Brass Marketing Coordinator

SOURCES INCLUDE:

https://brennaninc.com/selecting-instrumentation-fittings-valves-and-tubing/

https://www.titanfittings.com/articles/single-ferrule-or-dual-ferrule-which-one-to-use

https://rubberandspecialties.com/compression-fitting-types-and-applications/

https://blog.brennaninc.com/understanding-the-two-types-of-tube-fittings

https://www.dawsonstech.com/instrumentation-tube-fittings-5-things-you-should-consider/

3/4/2025 6:47:46 AM