"We needed a solution that balanced efficiency, safety, and availability without compromising on quality. The collaboration between JRT, Consolidated, and Merit Brass gave us confidence that the stainless press fittings would meet our rigorous standards for this food-grade facility," said Dan, Reser’s Fine Foods project manager.

Merit Brass has over 85 years of experience in serving the PVF (Pipe, Valve & Fitting) industry with high quality products which includes our NEXT GENERATION press fittings and valves. MeritPress™ available in copper, carbon and stainless press fittings and valves are engineered solutions designed to help you complete projects safely, on time, and in full.

Press fitting systems reduce project costs up to 30% due to labor and auxiliary material savings. They reduce the time it takes to install a system, address labor shortages, have reduced overhead, and are safe to use.

Press fitting installations are safe because there is no need to acquire an open flame permit with press fittings and valves. All that is required with a press system are the press fittings and/or valves, a press tool, and the accompanying press jaws/rings.

Merit Brass' press fittings and valves provide you with the most comprehensive press package. Our offering serves contractors working in residential and commercial plumbing and industrial applications.

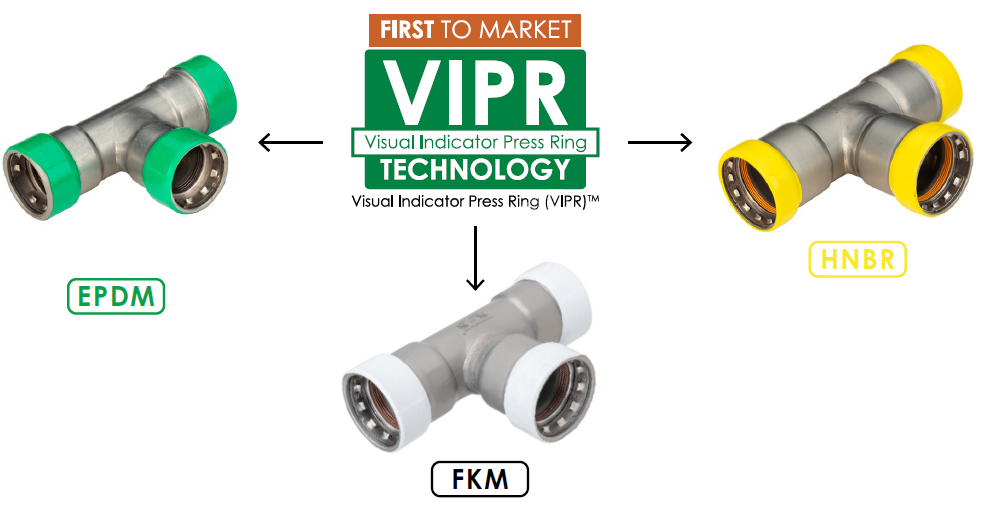

After listening to the voice of customers across varying applications, Merit's team of engineers developed the next generation of press fittings to enhance the installation process. We designed the Visual Indicator Press Ring (VIPR)™ to make it easy for the installer to identify any unpressed joints in the system.

Each press fitting and valve up to 2" has a Visual Indicator Press Ring (VIPR)™ that mirrors the sealing element and ensures proper installation. The ring can be easily removed after the fitting has been pressed. Fittings and valves 2.5" and above have an easily removable identification tag.

Our press fitting offering is available in the following alloys: stainless steel, copper, and carbon; and our press valve offering in stainless steel and copper alloys. Merit's innovative press offering, known as MeritPress™ is comprised of 3 alloys: Carbon, Copper, and Stainless.

Merit Brass' Carbon and Stainless press offerings are available in either sealing element; EPDM (Ethylene Propylene Diene Monomer) for water applications, HNBR (Hydrogenated Nitrile Butadiene Rubber) for gas applications, and FKM (Fluoroelastomer) for industrial applications. MeritPress in Copper is available in EPDM only. All MeritPress brands have the sealing element called out in the correct color on the bag, box, band/tag for ease of receipt. To learn more about MeritPress please click on the alloy below.

Merit Brass' NEXT GENERATION press offering has several benefits and features. Carbon press fittings are suitable for use on steel pipes conforming to ASTM A53, A106, A135 A795 (schedule 10 to 40 and black iron). Copper press fittings and valves in CTS (Copper Tube Size) is stamped for NSF61 on EPDM. Stainless press fittings and valves in IPS (Iron Pipe Size) is for use with schedule 10 or schedule 5 stainless steel pipe.

Additional Press Resources