How the Copper Alloy Benefits Your Piping Systems

The plumbing and PVF industries have a vast array of alloys that serve many applications. Merit Brass is always evaluating our offering of piping components to marry our customers’ needs with the challenges of these dynamic industries. Merit added press fittings and valves in copper (known as CopperPress®) to our offering to save our customers time, money, and labor.

Copper is a metal that possesses excellent corrosion resistance. In addition, copper has high mechanical strengths and high temperature resistance which makes it a great conductor of electricity. Copper can be easily customized to fit almost any application by combining other metals and adjusting the percentages creating copper alloys.

Alloy of Copper: What I Used in the PVF Industry

There are many different alloys of copper. Below are the main copper alloy families used throughout the plumbing and PVF industries:

- Brass (made up of copper and zinc), offers great strength and ductility, excellent corrosion resistance, and is easily cold worked; primarily used in plumbing applications

VISIT OUR BRASS PAGE

- Tin Brass (made of up copper, zinc (2% to 40%), and tin (0.2% to 3%)), is used to make high strength fasteners, electrical connectors, and mechanical products due to its increased corrosion resistance and excellent electrical conductivity

- Phosphor Bronze, also referred to as Tin Bronze (made up of copper, tin (0.5% to 11%), and phosphorous (0.01% to 0.35%), has great spring qualities, high fatigue resistance, excellent formability, and solderability for use primarily in electrical products

- Aluminum Bronze (made up of copper, aluminum (6% to 12%), iron (up to 6%), and nickel (up to 6%), provides high strength, toughness, and excellent wear and corrosion resistance for applications handling seawater, sour mine waters, nonoxidizing acids, and industrial process fluids

- Silicon Red Bronze and Red Brass (copper, zinc (less than 20%), and silicon (up to 6%), silicon red brass is typically used where strength tolerance and resistance to corrosion is critical whereas silicon red bronze has a lower zinc concentration and is used to make bearings, gears, and intricately shaped valve components

- Copper Nickel (made up of copper, (2% to 30%), and various amounts of iron, chromium, niobium, and/or manganese), is immune to stress corrosion and cracking, has extreme resistance to oxidation in steam and moist air, and is used in marine applications due to its corrosion resistance

- Nickel Silver, also referred to as Nickel Brass (made up of copper, nickel, and zinc), has an attractive silver luster, tolerance to high strengths, and excellent resistance to corrosion; it is typically used to make food and beverage handling equipment, decorative hardware, and musical instruments

What is the Copper Metal Used For?

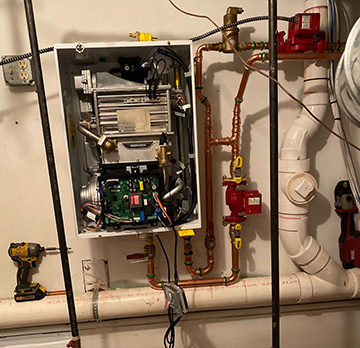

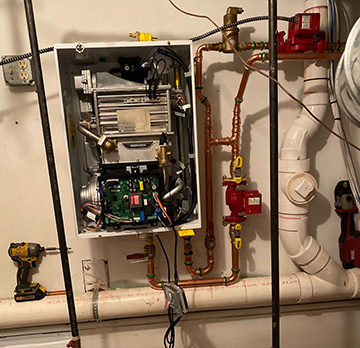

Copper is often used by contractors in plumbing, heating, and cooling applications because of its ductility and resistance to corrosion. Copper also serves many other applications, some of which include: industrial, fuel gas, marine, and electrical.

Characteristics of Copper Alloys

- Excellent electrical and thermal conductor

- Offers great formability

- Generally nonmagnetic

Reasons to Use Copper Alloys

- Offers great resistance to fatigue

- Used in the plumbing and PVF Industries to carry potable water, process water, or other liquids & gases

- Pure copper is used extensively for electrical wire and cable, electrical contacts, and various parts that are required to pass electrical current

Benefits of Copper Alloys

- Environmentally friendly systems

- Can be alloyed with other metals to increase hardness levels

- Antimicrobial

- Polished and buffed to almost any desired texture and/or luster

Merit Brass’ Copper Offering

Merit’s copper portfolio includes small diameter and large diameter press fittings and (small diameter) press end ball valves. CopperPress® fittings and valves are made of lead-free dezincification resistant copper. Our CopperPress® fittings and valves mate with ASTM B88 copper tube types L, K or M.

CHAT WITH AN EXPERT ON PRESS TODAY