If you're not sure which valve is right for your project or you have a bunch of questions about the different types of valves you can use, fortunately, we've developed this comprehensive guide to take you through all types of plumbing valve options. This guide can help you make recommendations and pass along knowledge to your customers and/or new hires, whether you're looking for valves to handle flow control in air, gas, water, liquid and hydraulic system plumbing.

In a piping system, a valve is a piping component or fitting that provides flow control. Valves, also known as pipe valves, are controlled by a manual (by hand), automatic (when specific flow condition is met), or actuated (remote control via electric, pneumatic/air, hydraulic or solenoids) system to open or close as needed. However, these fittings can also provide other types of flow control beyond whether it opens or closes to control flow.

In some cases, such as a pressure relief valve, it only opens when a high pressure situation occurs, so that excess pressure bleeds off instead of creating a dangerous situation. This type is used to help improve safety and regulate pressure.

As another example, a backflow preventer, also known as a check valve, allows water to flow freely in one direction, but prevents it from flowing backward through a pipe.

However, it's not only fluid flows that can be controlled by a valve. Air and various types of gas can also be controlled using this type of plumbing technology. Compared to fluid valves, most valves that control air and gas are a type of ball valve, which completely blocks the flow of matter using a quarter turn. This is because molecules of gas and air are typically under a high pressure compared to fluids and are able to get through smaller gaps, requiring a better-quality valve to keep the air or gas from leaking around the edges when it is closed while allowing flow control while it is open.

In some cases, like with a multi directional valve, you may be able to select whether the matter being transported is sent to one of several specific runs of pipe.

In summary, valves can start/stop flow, regulate flow & pressure, control the direction of flow, throttle flow rates, and improve safety pressure relief or vacuum in piping systems. However, within these types of valves are a wide variety of valve designs that serve a range of purposes.

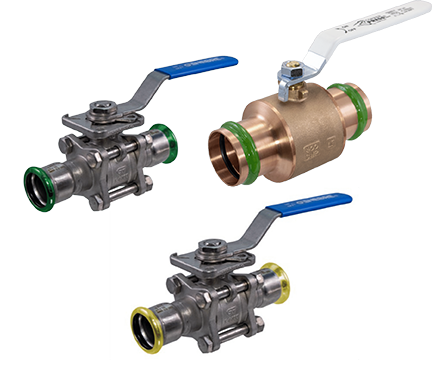

A ball valve, which is also known as a quarter turn valve, features a ball that has a hole drilled through the middle of it which turns in the center of the valve assembly. By turning the valve control 90 degrees, you move the ball in the center, either to align the hole with the piping system and allow flow or to turn the hole perpendicular to the piping system, stopping the flow. With this action, a single individual can stop or start the flow of liquid, air, or gas through the line. This allows very fast operation of the valve, so that it can be shut off quickly.

By comparison, a gate valve moves a small gate at the center of the valve up and down by use of a threaded control on the top. As the control is turned counterclockwise, the gate moves up, allowing water to flow through the valve and into the piping system. Eventually, it will stop moving easily when it is fully open.

Because each turn of the control creates a small movement of the gate, it provides great flow control, but is not a great option for having to quickly open or close the valve. In many ways, it's very similar to a plug valve, which we'll discuss in the next section, but without the same level of reliability.

As mentioned above, a plug valve has a similar action to a gate valve, where a wheel is turned and a plug, instead of a gate, is moved up or down to control the flow of the matter in the piping system. Considered to be more reliable than gate valves, they still provide the same level of flow control, but with a larger control wheel, can be moved more quickly than a gate valve.

This allows finer control of the flow of matter through the valve while still allowing a faster shutoff in an emergency, though not as quickly as with a ball valve. These types of pipe valves are also referred to as needle valves.

A butterfly valve contains a disc in the middle of the valve body and, like a ball valve, it rotates 90 degrees to provide flow control. However, given the thinness of the disc in the middle, these lightweight valves tend to have fairly short lifecycles without repair.

For this reason, they are best suited for temporary installations to help save costs, but not necessarily in permanent or long-term projects. However, always consult your project team prior to deciding which valves will be optimal to install.

With an action similar to a gate valve, a globe valve has a stopper that is moved down onto a point in the center of the valve body to stop flow. However, globe valves are typically much larger than other types, with a globose appearance that gives them their name. This is to maximize flow through the center of the valve body, so that flow is impinged as little as possible in the process.

A check valve is unique in that it isn't manually controlled in some fashion, but instead provides a mechanical way to prevent water or other matter from flowing backward through the pipe. They're fairly common on wells, where the weight of the water column would otherwise cause water to sink back down the well when it isn't actively pumping, as well as on irrigation systems to prevent fertilizers from contaminating well and ground water.

Though they're somewhat unusual, most commonly seen in sewer pipe and wastewater plants, pinch valves are used with flexible materials in the interior, which can be pinched off in the center to prevent matter from flowing through. This can be accomplished by mechanical means or by using a pneumatic or hydraulic system to force the flexible material together at a pressure greater than that of the water or other matter coming into the valve.

Valves are usually sized based on the surrounding piping component, whether that is stainless steel pipe, brass pipe, or other material. If you have 1" stainless steel pipe, you'll want to get a pipe fitting that will match that size, such as a 1" ball valve. Though there is some interplay between different types of piping, it's best to make sure that the fittings that you're buying, including your valves, will fit the piping system that you're working with.

An end connection is a means of connecting components within a piping system. Specific to valves, there are several types of end connections:

As you can see, there is a wide range of pipe valve styles, and selecting the proper one for your situation requires careful thought. Consider your client's applications and their situation before proceeding. If you're ready to take a look at what Merit Brass has to offer, please feel free to check out our website offerings or contact us for more details.

Authors: Authors: Kimberly Wallingford, Director of Marketing and Marcus Estrella, Director of Product Line Management

SOURCES INCLUDE:

3/28/2025 1:42:55 PM