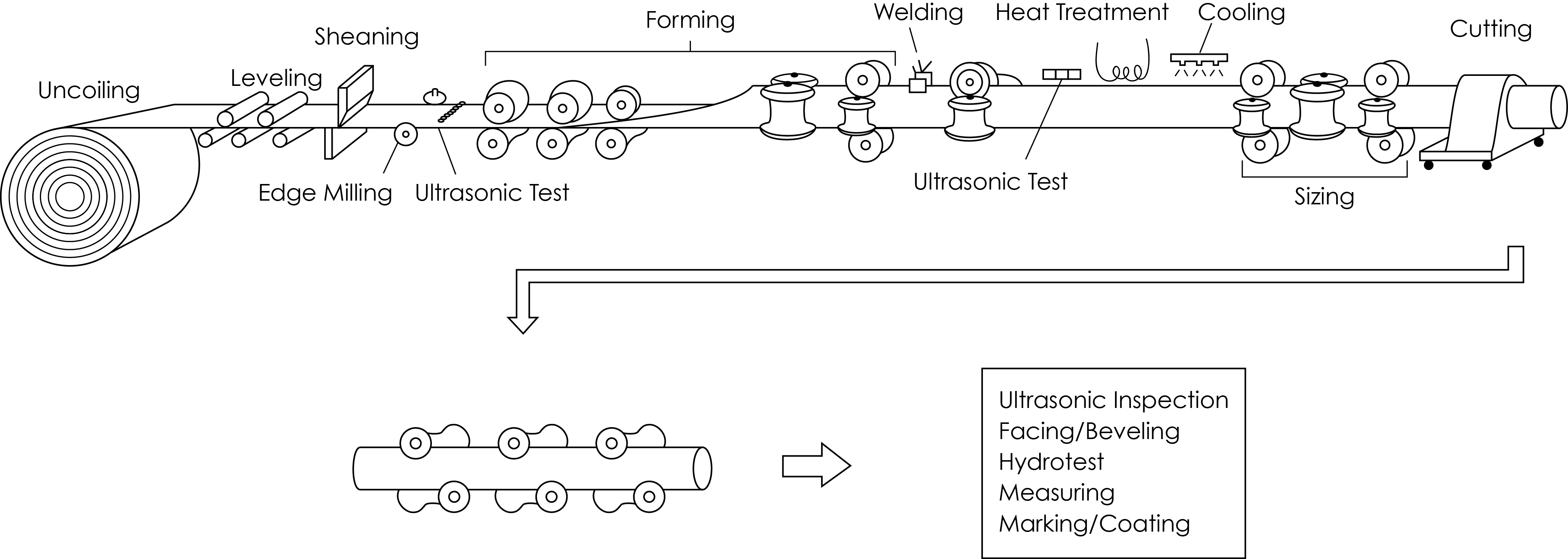

Two of the most common methods to produce pipe are Electric Resistance Welding (ERW), and Electric Fusion Welding (EFW). Both processes involve a coil of steel being continuously fed through a series of rollers/dies which shape the flat steel into the desired shape of the pipe.

How the edges of the steel plate are joined together are what makes the ERW and EFW processes different.

Over the course of this Blog, we will discuss both processes, the benefits each have, and why you would use ERW or EFW pipe.

As stated above, once the flat steel plate has been formed into the pipe shape the two edges need to be joined together.

In an ERW process, a high frequency electrical current is used to heat the edges of the steel plate just before the final shaping rollers/dies join them together to create the circular pipe shape.

A high frequency Is prevalent in modern piping because the low frequency current had several deformities including: seam corrosion, hook cracks and the seam bonding was inadequate.

ERW pipe has a weld seam that runs along the length of the pipe. ERW pipe will either clean/trim the weld seam, or just use a roller/die to smooth out the seam to match the outside diameter; leaving a visible weld seam on the inside diameter.

the weld seam, or just use a roller/die to smooth out the seam to match the outside diameter; leaving a visible weld seam on the inside diameter.

For EFW (also known as electron beam welding), an electron beam (laser) is used to heat the edges prior to the rollers/dies joining them together.

EFW pipe also has a weld seam that runs along the length of the pipe. This seam is cleaned/trimmed on the outside, and inside, diameter for EFW pipe.

EFW pipe is a cost effective solution for environments that require high pressure and are corrosive. This type of pipe has better strength and durability. This pipe is stronger, denser and more uniform as compared to ERW because of its fusion method.

Finally, the pipe continues to go through another few sets of rollers/dies to ensure its final shape before each section of pipe is cut to length.

The ERW manufacturing process is highly efficient and cost-effective. Machinery required for ERW pipe is very common, and with proper care and maintenance can run for decades. As a result, it is the predominant method for producing pipe in the PVF industry.

The fusion process in EFW manufacturing produces a much narrower “heat affected zone” in the pipe than the ERW process. This translates to a better uniformity of the metal in the pipe, and a higher pressure rating than ERW.

Combining the higher pressure, with a still cost-effective end product (the initial tooling investment is greater for EFW pipe), means that EFW pipe can be looked at as a substitute for seamless pipe in certain applications.

Just as ERW is the predominant pipe manufacturing process, ERW pipe can be found in just about every industry where fluid/media needs to be moved from one location to another.

Common industries where you would find ERW pipe include: plumbing, HVAC, fire suppression, commercial, aviation, aerospace, automotive, rail, electronics, energy, oil & gas, and industrial.

Being viewed as a cost-effective alternative to seamless pipe means that EFW can be used in higher pressure, more corrosive applications where ERW could not be considered. Industries such as petrochemical, textile, food & processing and chemical processing can utilize EFW in areas of their pipelines.

Other pipe standards, such as ASTM A53, ASTM A252, and ASTM A312 would apply to both ERW and EFW pipe.

It is important to understand the differences between ERW and EFW pipe to ensure that you are using the correct pipe for your system’s application. Pressure, corrosive environment and budget are just some of the considerations when determining which type of pipe to use.

Always consult your project and engineering firm prior to installing any pipe into your system to ensure a safe and proper installation.

Author: Kimberly Wallingford, Director of Marketing - Merit Brass and Marcus Estrella, Director of Product Line Management - Merit Brass

Sources:

SAW vs ERW and EFW Welded Steel Pipe (hu-steel.com)

https://www.oshwin.com/stainless-steel-efw-pipe.html

Stainless Steel EFW Pipe | SS 304/316 EFW Pipe (oshwin.com)

PHMSA: Stakeholder Communications - Manufacturing Process (dot.gov)

What are the main equipment in the erw pipe production line? (eastern-steels.com)

2/7/2025 7:26:08 AM