Copper tube coils play a fundamental role in the pipe, valve, and fitting (PVF) industry. Their durability and reliability make them crucial for various applications, including plumbing, HVAC, and industrial piping systems. For wholesale distributors, copper tube coils are more than just another inventory item. They are essential for contractors, engineers, and installers who need quality materials for plumbing, heating, cooling, and industrial systems. This blog will explore the role copper tube coils play within the PVF industry and highlight their unique advantages.

Copper tube coils provide distributors with the ability to:

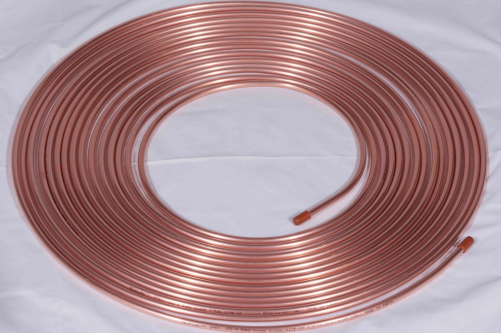

Copper tube coils are spiral-shaped tubes made from copper extensively used in various industrial applications including the transport of water, gas, and refrigerants. They are beneficial because of their coiled design which allows for easy storage and transportation. Copper tube coils play an essential role in heat exchangers for plumbing and HVAC applications. This is because of their excellent heat transfer. The inherent properties of copper make copper tube coils necessary across many industries because of its:

Available in various sizes and thicknesses, copper coils are versatile enough to meet diverse industrial needs such as:

EXPLORE OUR COPPER TUBING & COILS

Copper tubing and copper tube coils are essential components in various industrial, residential, and commercial applications because of their durability and reliability. Copper tube coils are classified based on the type of copper being used. Copper tube coils sold at the wholesale level are predominantly soft annealed. Hard drawn coils can be purchased, but generally come pre-formed for a specific shape and application.

Copper tubing comes in two main forms, defined by their temper (strength and hardness of the tubing):

Learn More About Copper Tubing

Copper tube coils are widely used in the PVF industry because of their formability and malleability which makes them ideal for systems that deliver drinking water or handle gas. Wholesale distributors often supply copper tube coils for a wide range of applications, including:

Copper tube coils have many benefits that make them an excellent choice for wholesale distributors in the PVF industry.

In conclusion, copper tube coils offer a robust, reliable, and versatile solution for wholesale distributors in the PVF industry. Whether used in plumbing, HVAC, or industrial piping systems, these components provide long-term durability, efficiency, and safety. Understanding the benefits of copper coils can help wholesale distributors in selecting the right product for their customers' needs.

If you are planning a project that requires copper coils, reach out to our family of talented sales associates. Embrace the potential of copper coils for improved performance and efficiency in your projects!

Author: Hedy Hemlick, Marketing Coordinator - Merit Brass

Q: What is the difference between copper coils and copper pipe?

A: Copper coils are spiral-shaped tubes made from copper and provide great formability and malleability. Copper pipe is a straight pipe made from copper and requires pipe fittings to be used around corners because they are not easily bendable.

Q: What is the clear liquid that is applied to copper coils and what is its purpose?

A: It is a type of coating that can include polyurethanes, epoxies, fluoropolymers, and silanes. While each type of coating has its own pros and cons, these coatings are applied as a shield to prevent coil corrosion and to protect the longevity of the coils.

Q: What type of copper tubing is used in HVAC systems?

A: Type K copper tubing and Type L copper tubing can both be used in HVAC systems. Type K copper tubing is recommended because of its thick wall which provides excellent durability and the ability to withstand pressure. Type L copper tubing is also recommended because of its durability, but more importantly its flexibility due to its thinner wall compared to Type K.

Sources:

https://www.copper.org/publications/pub_list/pdf/copper_tube_handbook.pdf

Custom Copper Coils |Secondary Copper Coil Services (hbrindustries.com)

Copper Coils | Metal Associates | Material Options

Use Of Copper Alloys In Oil And Gas Process Facilities

Antimicrobial Properties (copper.org)

Differences between Copper Coils and Copper Pipes - HVACR Wholesale Dealer & Supplier UAE

Preventing Coil Corrosion | Just Venting

The Most Common Types of Copper Tube: K/L/M | LinkedIn

11/1/2024 11:32:07 AM