In fluid control systems, choosing the right valve is important in ensuring safe and efficient operation. One of the key considerations when selecting a valve is the port size. This guide will walk you through the key differences between full port, standard port, and reduced port ball valves. It will include how they work, where they are most used, and why one type may be better suited for a specific application compared to another.

operation. One of the key considerations when selecting a valve is the port size. This guide will walk you through the key differences between full port, standard port, and reduced port ball valves. It will include how they work, where they are most used, and why one type may be better suited for a specific application compared to another.

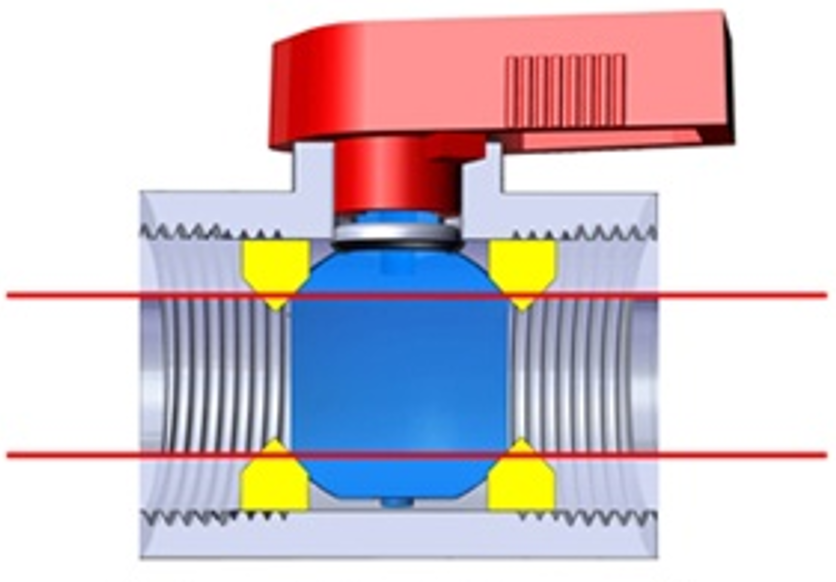

In a piping system, the port refers to the opening that fluid flows through when the valve is in the open position. It is a critical component because the size directly impacts the system’s flow rate, pressure drop, and energy efficiency. Different ports have distinct functions contributing to the safety, efficiency, and the functionality of the system.

The size of the valve port compared to the pipe’s diameter determines how much flow resistance is introduced into the system. This can influence the overall performance, maintenance requirements, and operating costs. Let’s explore below in further detail more about certain types of ports and their functions.

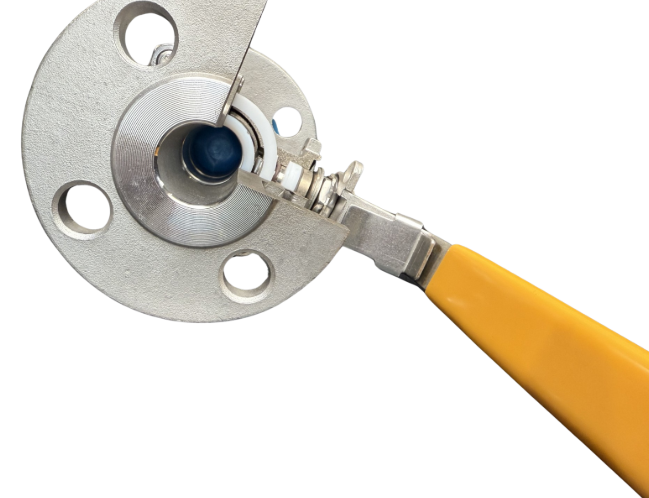

A full port (also known as a full bore) ball valve has a port with a diameter equal to the inside diameter of the pipe it connects to. While the valve is fully open there is an unrestricted flow path which allows the fluids to flow through without any narrowing. This design results in minimal pressure drop, which is ideal for systems where high flow rates and efficiency are a priority.

A full port (also known as a full bore) ball valve has a port with a diameter equal to the inside diameter of the pipe it connects to. While the valve is fully open there is an unrestricted flow path which allows the fluids to flow through without any narrowing. This design results in minimal pressure drop, which is ideal for systems where high flow rates and efficiency are a priority.

Full port ball valves serve a variety of industries, some of which include: oil & gas, chemical processing, water treatment, power generation and food and beverage production. It is also worth noting that ball valves are not the only type of valves that use a full port. Gate valves and some other types of plug valves may also use full port design to achieve similar flow characteristics.

The flow direction in full port valves is bidirectional. Bidirectional means that the design of the valve allows fluid to flow through it in either direction. This makes it easy to install into systems without worrying about the direction of flow.

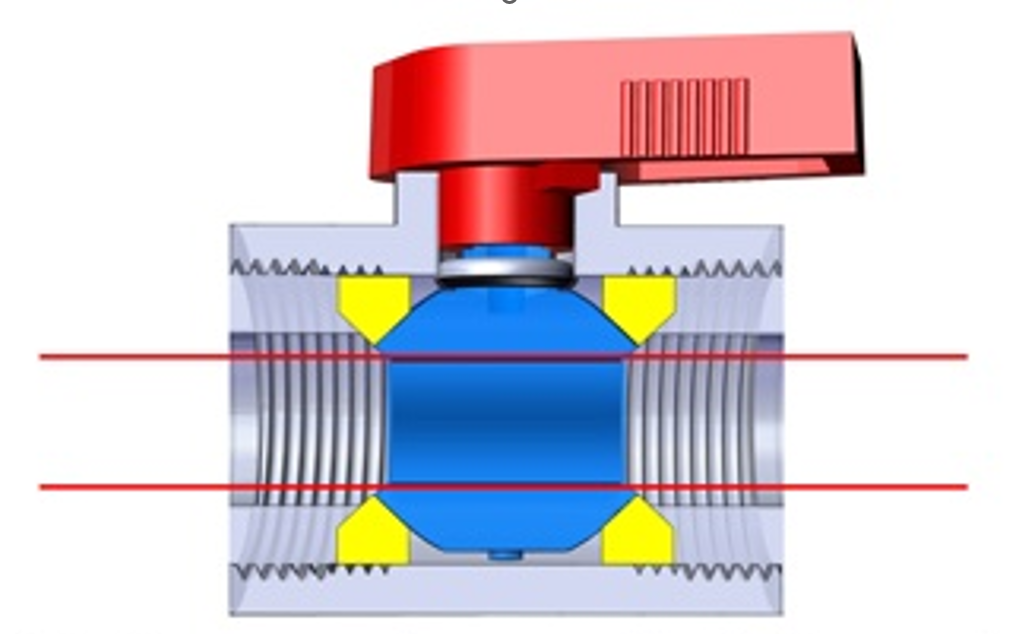

A standard port ball valve has an inner ball that has a slightly narrower bore diameter than the pipeline’s inner diameter. While it still provides good flow control, it also moderately reduces the pressure compared to a full port valve. A standard port ball valve is suitable in medium pressure systems where maximum flow is not essential and are suitable where space and costs are considered.

the pressure compared to a full port valve. A standard port ball valve is suitable in medium pressure systems where maximum flow is not essential and are suitable where space and costs are considered.

Standard port ball valves serve a variety of industries, some of which include: HVAC systems, residential & commercial plumbing, and manufacturing. Although standard port valves are not suitable for applications that require maximum flow rates, they are often the preferred choice when budget and size constraints are a concern. Ball valves are not the only type of valves that use a standard port. Globe valves and butterfly valves usually use a standard or reduced port to reduce cost and save material.

The flow direction in standard port valves is also bidirectional. Again, bidirectional refers to the upstream and downstream flow of the medium. Conversely, unidirectional valves are designed to allow the flow in one specific direction only.

Reduced port (or reduced bore) ball valves have a significantly smaller bore diameter than the pipeline’s inner diameter. They are designed to intentionally restrict flow and lower pressure. A reduced port ball valve is used when a controlled flow is necessary, they are ideal for low flow or precise systems.

Reduced port valves are often smaller in size, cost saving, and lighter weight. Reduced port ball valves serve a variety of industries, some of which include: laboratory systems, small scale industrial processes, and chemical dosing.

Because of the significant flow restriction these types of valves are not appropriate for high-capacity flow systems. Ball valves are not the only type of valves that use a reduced port. Needle valves and some globe valves may also use reduced ports for a more precise and fine flow control.

Like the other types, reduced port ball valves also are bidirectional. Bidirectional ball valves have sealing surfaces on both ends of the ball. Regardless of the direction of flow, this ensures a tight closure.

Understanding the difference between full, standard, and reduced port ball valves helps engineers and operators make informed decisions based on system pressure, flow requirements, and cost. Here is a quick summary:

When selecting the right ball valve, consider the systems pressure and flow requirements, as well as space and budget constraints. Choosing the correct port type can improve system efficiency, reduce maintenance, and lower long term operational costs. It is important to note that there are several valves in the PVF industry, other valves do not have a port in the same way that a ball valve does.

Do you need help choosing the right ball valve or port size? Contact our sales team for more information on our inventory of ball valves and various ports.

Authors: Addison Towne, 2025 Summer Marketing Intern and Marcus Estrella, Director of Product Line Management, Merit Brass Company

Sources:

5/28/2025 10:02:36 AM