Due to its long-term value and reliable performance, copper tubing is a top choice amongst contractors working in the plumbing and heating & cooling systems.

As the leading choice of contractors in plumbing and heating & cooling installations, there are many advantages of using copper tubing within residential and commercial buildings. From its ductility and resistance to corrosion, this material is a high-quality choice that will span a long lifetime.

Copper is a lightweight material which allows professionals to transport the product easily.

Because of its ductility, it can be easily bent and formed to shape without causing any fractures hence its common use with water applications.

Due to its ability to easily bend and its lightweight material, it is a popular choice by contractors because of its trouble-free service and ease of installation.

Possesses excellent corrosion and high temperature resistance along with high mechanical strength.

Since copper tubing is manufactured from recycled materials, it can be recycled at the end of its lifespan which results in less dangerous emissions and chemicals being released into the environment.

Water does not get contaminated because the dangerous materials were removed in the beginning of the manufacturing process.

There are a few ways that copper tubing can be manufactured but it all depends on economic factors such as the cost, availability, and the furnace capabilities. The manufacturing process begins with copper (raw material) which is created from the following materials: copper scrap, newly refined copper (also referred to as cathode copper or cathode), or copper ingots.

After the copper wire is recycled, it is stripped of its insulation resulting in the formation of copper scrap. While copper scrap is a relatively clean material, it does contain some impurities which include zinc, tin, nickel, and even some iron. Only the highest quality grades of copper scrap are used when manufacturing copper tubing.

Manufactured in large electrolytic cells that refine impure blister copper taken from smelting and refining furnaces.

Mainly used by tube mills and bears a strong resemblance to large brick casts from re-melted cathode or refined scrap.

The raw copper is then melted in a furnace to remove any impurities. Once it has been purified, it is transferred into a cast to solidify. After it has hardened, it is removed from its casting to get resized and cleaned up.

There are many ways to cut copper tubing, however, factors such as cost, capabilities, and type application should be taken into consideration. One of the most common ways is to use a tubing cutter because of the ease of use. Using a tubing cutter works best in close quarters as it results in straight and even cuts, as well as doesn’t deform the shape of the tube.

In the plumbing industry, copper tubing is measured by the outside diameter (OD) and wall thickness. Types K, L, M, and DWV must comply with ASTM standard sizes, but the actual outside diameter is always 1/8 inch larger than the standard size. For use in the air-conditioning and refrigeration field service (ACR), it is designated by the actual outside diameter.

The term temper describes the strength and hardness of the tubing.

Hard Temper, often referred to as “drawn”, is joined by soldering, brazing or welding. Tubing in the hard temper condition can also be joined by a variety of mechanical joins that can be assembled without the use of the heat source that is typically required by soldering and brazing.

Soft Temper, often referred to as “annealed”, is joined by the same techniques as hard temper but is also joined using flare-type and compression fittings. Just like the hard temper condition, the soft temper condition can be joined by a variety of mechanical joints without the heat source used by soldering and brazing. It is also extremely malleable because the annealing process softens the tube.

To determine which type of copper tubing you should use for a particular application, consider the strength, formability, wall thickness, and other mechanical factors. Plumbing and mechanical codes will also determine which type should be used in your project.

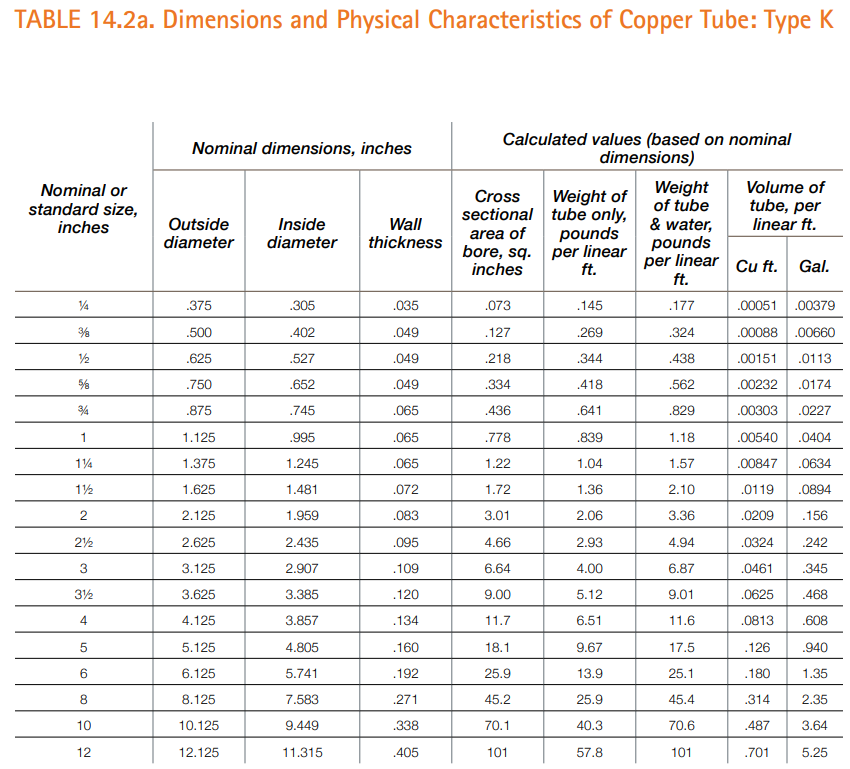

Type K has the thickest walls out of all copper tubing. It is used in main water lines, as well as fire protection, oil, HVAC, and many more applications throughout the construction industry. Its durability and wall thickness are why it helps withstand pressures felt in water lines and underground installations. To comply with governance standards, the color code for Type K is green and meets ASTM B 88 Standard.

Source: Page 66, Copper.org’s Copper Tube Handbook

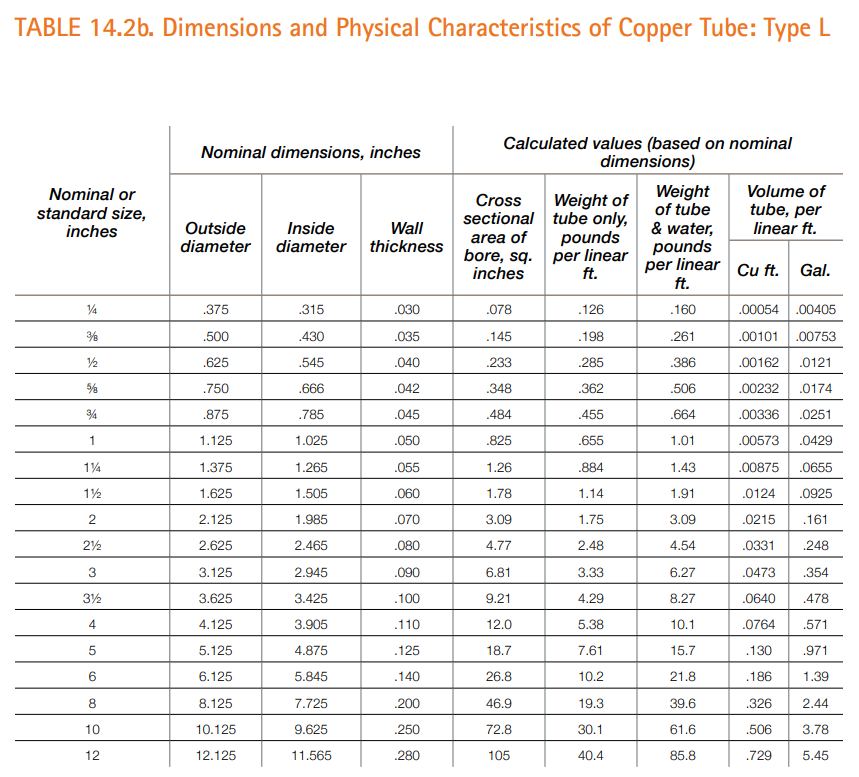

Type L is considered the most common type of copper tubing. While it does not have as thick of walls as Type K, it does have thicker walls than Type M. It is best for interior plumbing applications as well as fire protection and various HVAC applications. Type L is traditionally used with CopperPress®, by Merit Brass Co.’s fittings and valves. To comply with governance standards, the color code for Type L is blue and meets ASTM B 88 Standard.

Source: Page 67, Copper.org’s Copper Tube Handbook

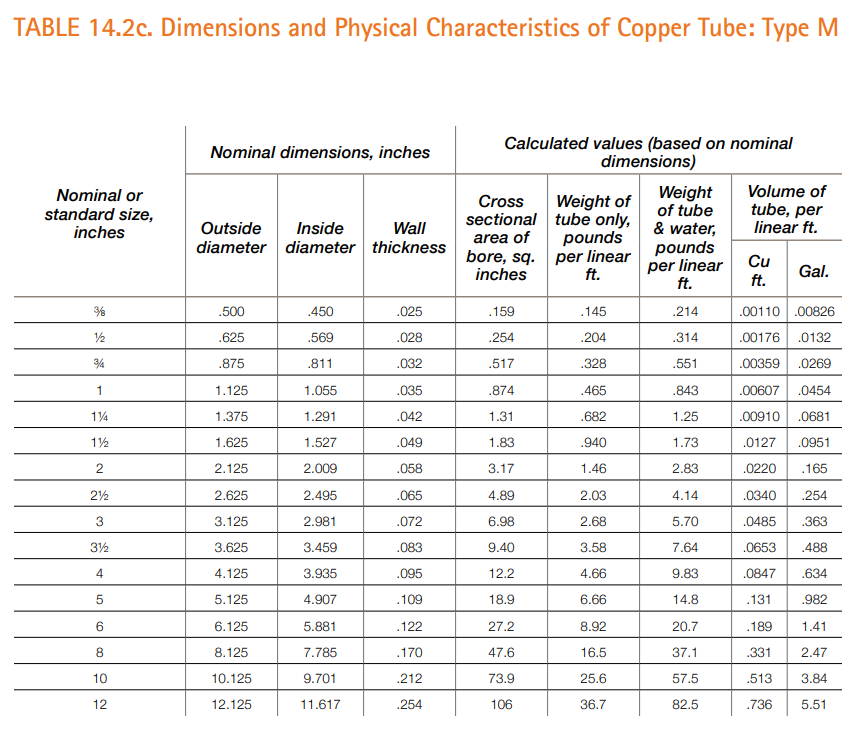

Type M has a thinner wall compared to both Type K and Type L. Because of its low costs, ease of use, and malleability, Type M is often used for repairs, replacements, and extensions to interior water supply lines as well as residential applications. To comply with governance standards, the color code for Type M copper tubing is red and meets ASTM B 88 Standard.

Source: Page 68, Copper.org’s Copper Tube Handbook

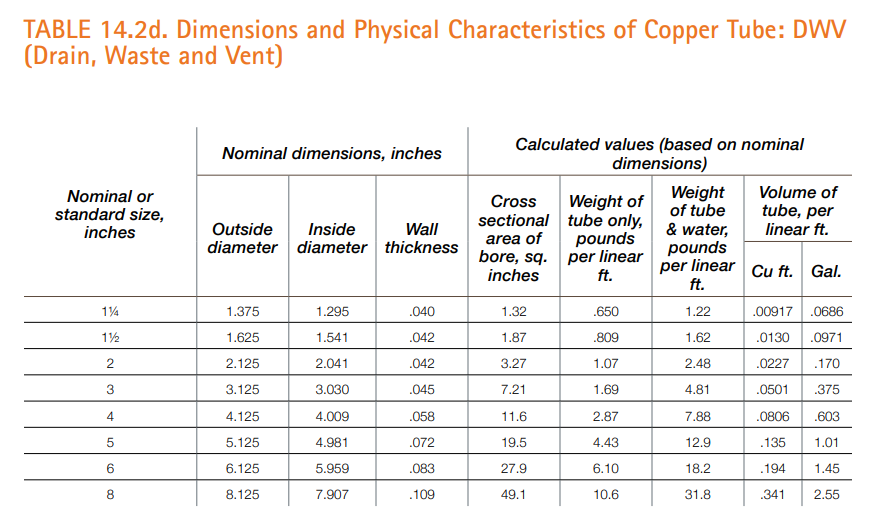

DWV is approved for use only in drain and vent lines typically found in older homes; it is not used in water systems. DWV has thinner walls than Type K, Type L, and Type M; and a maximum pressure rating of 15 PSI. To comply with governance standards, the color code for DMV is yellow and meets ASTM B 306.

Source: Page 69, Copper.org’s Copper Tube Handbook

Types K and L are often used in compressed air, natural gas, and liquified petroleum (LP) gas applications. Type K is used for underground applications while Type L is used for interior applications. While Types K, L, and M are all suited for the following applications, there is a preferred type to use. Type M is preferred for domestic water service applications. Type L is preferred for fuel/fuel oil applications. Type L is preferred for HVAC applications. Type DWV is used for drain, waste, and vent applications as it has the thinnest wall compared to Types K, L, and M.

Copper Tubing in copper tube size (CTS) is the ideal mate for CopperPress®, Merit Brass' line of copper press fittings and valves. Not only are CopperPress® fittings and valves safe and easy to install, but they will also save your customers time and money. Because they are easy to use, copper press fittings and valves address labor shortages as well as the amount of time and money saved on installations. CopperPress® fittings and valves are also very safe to use as they don’t require a burn permit and the system can also be wet when installation occurs.

The sealing element for press fittings identifies which applications they are most suitable for. Since copper press fittings are traditionally used in potable water applications, they have the EPDM sealing element. For press fittings used in gas applications, they have the HNBR sealing element. The color code for the EPDM sealing element is green and the HNBR sealing element is yellow. In addition, Merit's CopperPress® fittings and valves have a patented Visual Indicator Press Ring® (VIPR®) that is color-coded to match the sealing element and box & bag labels for ease of receipt and installation.

EXPLORE COPPER PRESS FOR YOUR INVENTORY

Authors: Kimberly Wallingford, Director of Marketing and Marcus Estrella, Director of Product Line Management

https://www.copper.org/applications/plumbing/benefits/

https://www.bobvila.com/articles/copper-pipe-types/#:~:text=Type%20L%20Copper%20Pipe,replace%20or%20repair%20water%20lines.

https://www.thomasnet.com/articles/pumps-valves-accessories/types-of-copper-tube/#:~:text=Copper%20tubes%20are%20used%20in,are%20available%20in%20specialty%20alloys.

https://www.thespruce.com/types-of-copper-piping-844852

https://www.copper.org/applications/plumbing/cth/standard-tubes/cth_1stand_type.html

https://monroeengineering.com/blog/how-copper-pipes-are-manufactured/

https://www.wmhendersoninc.com/blog/plumbing-tip-pros-and-cons-of-copper-piping/

https://www.protoolreviews.com/how-to-cut-copper-pipe/

2/26/2025 10:56:43 AM