Data centers are no longer niche facilities tucked behind office parks. Between hyperscale cloud growth, colocation expansion and the rapid rise of AI workloads, data center construction is accelerating well beyond traditional commercial building cycles. As these facilities scale, their mechanical infrastructure, especially cooling systems, has become more complex, more liquid-intensive, and far less tolerant of failure.

One noticeable result of this shift is the growing specification of stainless-steel ball valves across data center cooling and water systems. This article explains what’s driving that change, why ball valves play such a central role in data center cooling, and what it means for PVF wholesalers, engineers and contractors working on these projects.

From 2026 and beyond, data center growth is being driven by three factors; hyperscale cloud expansion, colocation demand, and AI workloads that dramatically increase heat density. Higher rack densities often exceeding legacy design assumptions are pushing cooling strategies away from the air only approaches toward liquid cooling and hybrid systems.

Liquid cooling doesn’t just add equipment; it multiplies piping circuits, isolation points, manifolds, and control components. Chilled water plants, glycol heat rejection loops, coolant distribution units (CDUs), and rack-level manifolds all depend on reliable piping systems to operate continuously.

For mechanical designers and builders, this means:

In that environment, material selection and valve performance matter more than ever.

Ball valves have become the dominant isolation valves in data center cooling systems for practical, not just theoretical reasons.

In chilled water, glycol, and liquid cooling loops, ball valves provide:

From an engineering standpoint, ball valves support system reliability and maintainability. From a contractor’s perspective, they are faster to install. From a facilities manager’s perspective, they are easier to operate and service than many multi-turn alternatives. For wholesalers, they represent one of the highest-velocity and most frequently specified valve categories on data center projects.

The move toward stainless steel ball valves is not about aesthetics or over-engineering, it’s about risk management in liquid-based cooling systems.

Modern data center cooling loops often involve:

These environments increase the risk or corrosion, scaling, and material incompatibility. Stainless Steel, particularly Type 316 and 316L, offers superior resistance to chlorides and chemical exposure compared to carbon steel and better long tern stability than any bronze alloys.

For engineers, stainless steel improves system life and reduces the likelihood of corrosion related leaks. For contractors, it means fewer callbacks and less rework. For facilities managers, stainless steel reduces the risk of corrosion-induced failures and leaks in cooling fluids which leads to lower maintenance costs, fewer emergency repairs and greater long-term confidence in system integrity. For wholesalers, stainless steel shifts the conversation away from lowest first cost and toward reliability, availability, and lifecycle value.

What Types of Data Centers Use Stainless Steel Ball Valves and Why?

What Types of Data Centers Use Stainless Steel Ball Valves and Why?Not all data centers are identical, but stainless-steel ball valves are most common in the segments where reliability expectations are highest. For many facility managers this means durability, corrosion resistance & high performance to help minimize unplanned downtime and maintain uninterrupted operation.

These facilities are designed for long operational life, repeatable campus builds, and minimal downtime. Stainless ball valves are favored for their corrosion resistance, consistency, and compatibility with treated water and glycol systems.

Colocation operators prioritize flexibility and uptime. Cooling systems must support frequent reconfiguration without introducing leak risk. Stainless ball valves support modularity and maintenance without compromising reliability.

As direct to chip and rear-door heat exchange systems become more common, liquid is brought closer to IT equipment. In these environments, leak tolerance is extremely low, making stainless components the preferred choice.

DEEPEN YOUR DATA CENTER KNOWLEDGE

When Engineers specify stainless ball valves, they are not just choosing a material they are selecting a set of performance expectations.

|

ASME B16.34

|

Confirms pressure temperature ratings and valve construction |

Ensures the valve body and materials can handle chilled water and glycol operating conditions over long service lives |

|

API 608 |

Establishes performance and testing expectations for metal ball valves |

Supports consistent shut-off performance and reliability across large, multi-building campuses. |

|

ISO 15848-1 |

Valve has undergone stringent third-part testing proving exceptionally low external leakage from stem seals & body joints |

Reduces external leakage risk in live environments where even small leaks can create operational issues. |

|

API 607 |

Verifies fire-safe performance |

Helps maintain pressure integrity and limit escalation during fire events in critical operational issues. |

|

NSF/ANSI 61& 372 |

Confirms suitability for contact with potable or makeup water. |

Supports compliance in water treatment and makeup water systems commonly found in data centers. |

For engineers, these specifications reduce uncertainty, improve safety margins and streamline approvals.

Data centers operate continuously, and maintenance often occurs in live environments. Valve selection directly affects installation and service safety.

From a contractor’s perspective, stainless ball valves offer:

From an engineering perspective, stainless materials reduce the likelihood of leaks caused by corrosion or material degradation, improving overall system reliability.

For facility managers where 24/7 uptime is key and maintenance must occur in live, pressurized systems. Stainless quarter-turn ball valves enhance safety and reliability by enabling quick, positive isolation of cooling loops, minimizing fluid spills during service and allowing for in-line seat replacement without a full system shutdown or pipe cutting. This reduces technicians’ exposure to hazards, lowers emergency repair risks and supports uninterrupted operations.

For wholesalers, stocking valves that support safe installation and maintenance positions them as partners in risk reduction, not just product suppliers.

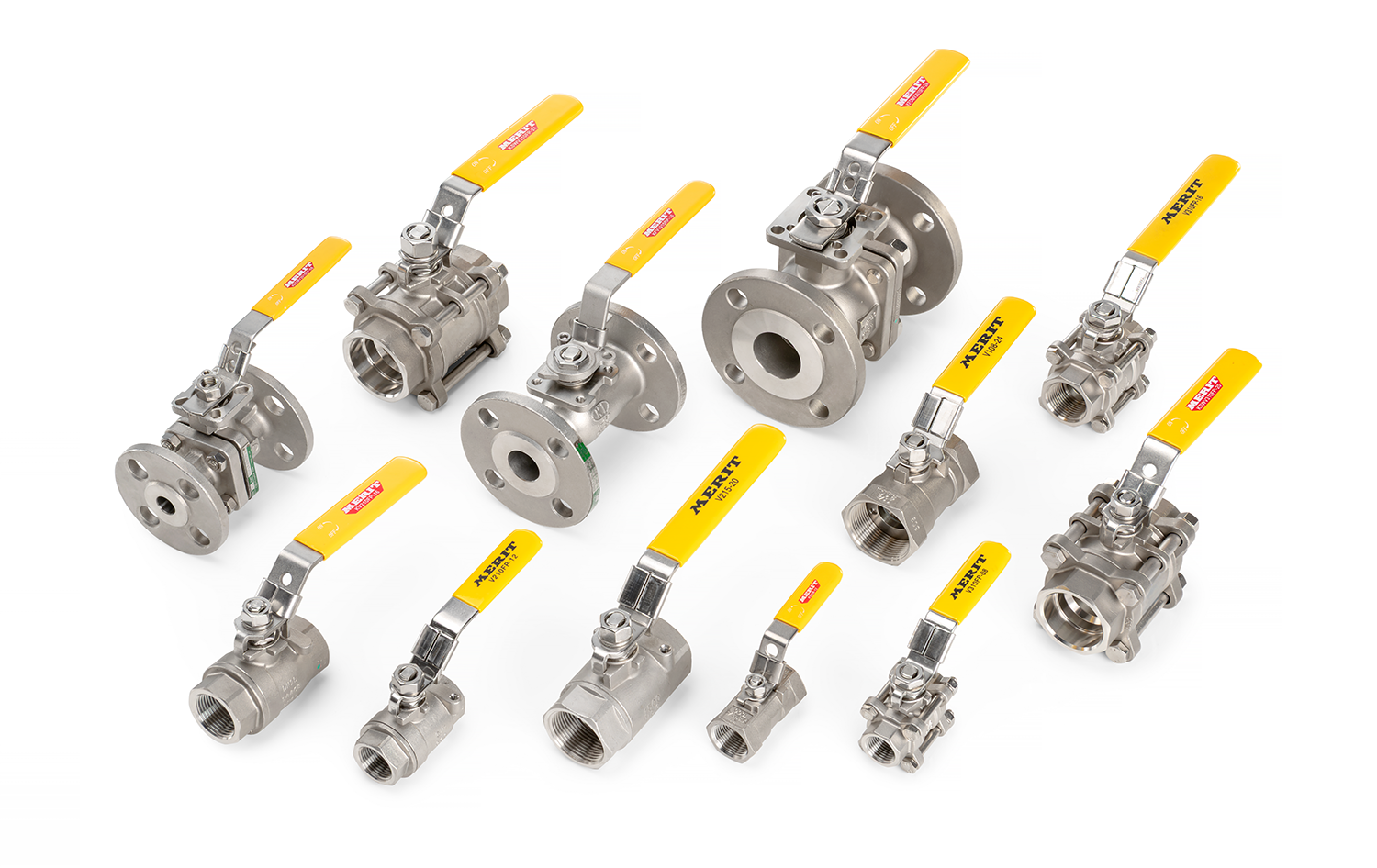

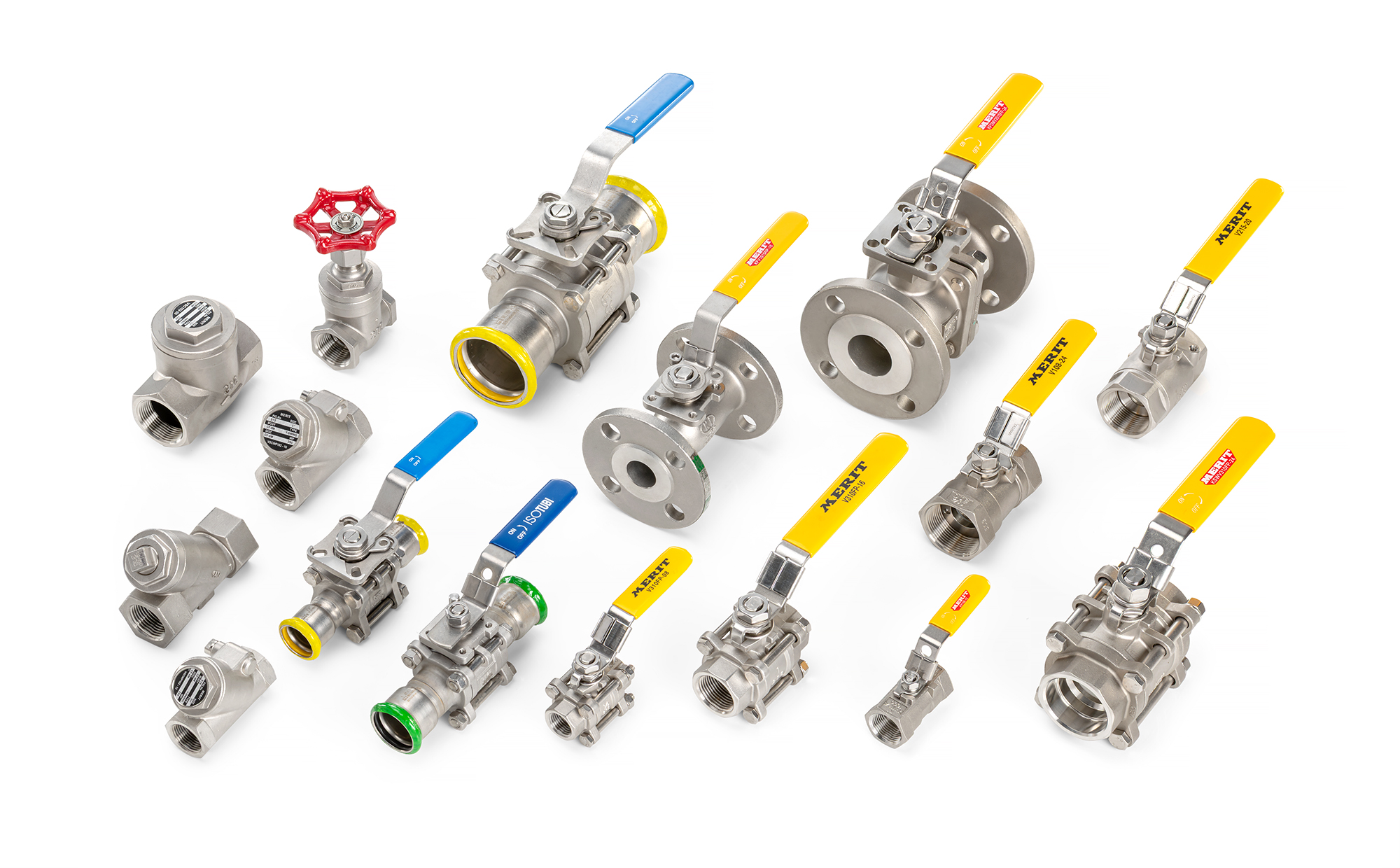

Several stainless ball valve configurations are commonly used across data center applications:

|

Ball Valve Type |

Typical Use |

Advantages |

Disadvantages |

|

Branch isolation, coils |

Compact, cost-effective |

Limited Serviceability |

|

|

CDUs, manifolds |

Easy maintenance, high cycle |

Higher cost |

|

|

Larger mains |

High intensity |

Requires alignment |

|

|

Sanitary (Tri-Clamp) Valve (NOT AVAILABLE AT MERIT) |

Clean liquid loops |

Fast installation, hygienic |

Pressure limitations |

Selection depends on system design, maintenance strategy, and reliability requirements.

Valve demand in data centers clusters around predictable size ranges:

For wholesalers, this means most sales volume is concentrated in smaller size, while larger valves drive a disproportionate share of project revenue.

What Data Center Buyers Look for in a Stainless Ball Valve

What Data Center Buyers Look for in a Stainless Ball ValveData Center Buyers are spec-driven and risk averse. Key priorities include:

Price matters, but reliability and schedule certainty matter more.

Sustainability in data centers focuses on energy, water, and lifecycle efficiency. Stainless steel ball valves contribute by:

Durable, recyclable materials also align with long term ESG (Environmental, Social & Governance) objectives, which are increasingly shaping how data center operators think about sustainability, risk, and infrastructure lifecycle decisions.

In practice, these choices support efficiency and reliability without forcing trade-offs in system performance.

For PVF wholesalers, data centers represent a rare opportunity to move away from transactional selling and toward long-term program business.

Stocking stainless steel ball valves:

Wholesalers who understand why stainless is being specified and stock accordingly are better positioned to win and retain data center customers.

Stainless steel ball valves enhance reliability in active data center systems by using highly polished, corrosion-resistant internal surfaces that limit particle buildup and prevent issues such as scale formation, biofilm growth, and flow obstruction. This helps maintain stable flow, pressure, and thermal conditions—key factors for maximizing uptime.

Additionally, their durable construction and bi-directional, tight-sealing design support high pressure operation and provide dependable shutoff performance, minimizing the likelihood of leaks or equipment disruptions.

300-series stainless steel offers strong inherent corrosion resistance, making stainless steel ball valves well-suited for the full range of cooling fluids commonly used in modern data centers. They perform reliably with treated water systems, glycol-based mixtures, and the newer liquid cooling media being deployed in AI and high-density environments.

Industry chemical-compatibility data consistently shows that stainless steel maintains stability when exposed to water, alcohols, glycols, and many of the byproducts formed as glycols age. This broad chemical tolerance makes stainless steel ball valves a dependable choice for contractors and operators who need a single valve platform that can support multiple cooling chemistries throughout a facility.

Corrosion in chilled water and liquid cooling loops degrades pipes and components, introduces iron oxides that clog heat exchangers/pumps, and increases leak risks leading to unscheduled downtimes.

Stainless steel forms a chromium oxide passive layer that dramatically resists corrosion, unlike carbon steel, aluminum, or copper alloys that deteriorate faster.

Corrosion in chilled-water and liquid-cooling loops can quickly compromise system performance. As metals break down, they release rust and other particulates that can clog heat exchangers, restrict pump performance, reduce flow, and increase the likelihood of leaks — all of which pose significant risks to uptime in data-center operations.

Stainless steel mitigates these issues by forming a stable, self-healing chromium-oxide film on its surface. This passive layer provides far stronger protection than materials like carbon steel, aluminum, or copper alloys, which tend to corrode more rapidly under typical cooling-loop conditions. For that reason, stainless steel components — including ball valves — are preferred when long service life and corrosion resistance are critical.

Stainless steel ball valves deliver more dependable shutoff performance in data-center cooling loops because their stainless-steel ball and PTFE seat combination provides true bubble-tight sealing with minimal operating torque. The precision machining of the valve body and internal components keeps the ball and seats aligned, helping the valve operate smoothly even under fluctuating pressures or temperature changes.

Their wear-resistant construction also helps protect the sealing surfaces over time, reducing the chances of seat damage, leakage, or performance drift. The result is a longer-lasting valve that maintains consistent shutoff capability—critical for keeping water-circulation systems stable and avoiding unplanned maintenance interruptions.

Brass and bronze valves can function adequately in lighter-duty systems that circulate only treated water at moderate temperatures. However, when these alloys are exposed to glycol blends, chloride-rich environments, or the newer liquid-cooling formulations used in high-density and AI-focused data centers, they are much more susceptible to dezincification, pitting, and overall accelerated corrosion. These problems can lead to leaks, unplanned service work, and higher lifecycle costs.

For mission-critical cooling applications, stainless steel — particularly 316-grade ball valves — is strongly preferred. Stainless steel offers significantly better corrosion resistance, greater mechanical durability, and broad compatibility with treated water, glycol solutions, and emerging dielectric coolants. This makes stainless steel valves a more reliable long-term option for facilities where uptime, leak prevention, and system stability are non-negotiable.

Authors: Saron Girma, 2025 Marketing Intern, Merit Brass Company and Kimberly Wallingford, Director of Marketing

SOURCES INCLUDE:

Emergence and Expansion of Liquid Cooling in Mainstream Data Centers

How Stainless Steel is a Necessity for Cooling Systems in Data Centers — Titan Cooling

Liquid Cooling Fittings, Valves, & Tubing for Data Centers

Data Center Valves | Emerson US

https://www.ashrae.org/technical-resources/bookstore/datacom-series

https://www.ashrae.org/technical-resources/ashrae-journal

https://www.asme.org/codes-standards/find-codes-standards/b16-34-valves-flanged-threaded-welding-end

https://www.api.org/products-and-services/standards

https://www.api.org/products-and-services/standards

https://www.worldstainless.org

1/19/2026 2:05:18 PM