In all good piping systems, preventing reverse flow is necessary for protecting equipment and maintaining system efficiency. One of the most common solutions for this is a swing check valve.

A swing check valve is a type of non-return valve that allows liquid or gas to move in one direction only. These types of valves require no external power because they are automatic. The swing check valve is usually a full port valve.

What is a Swing Check Valve?

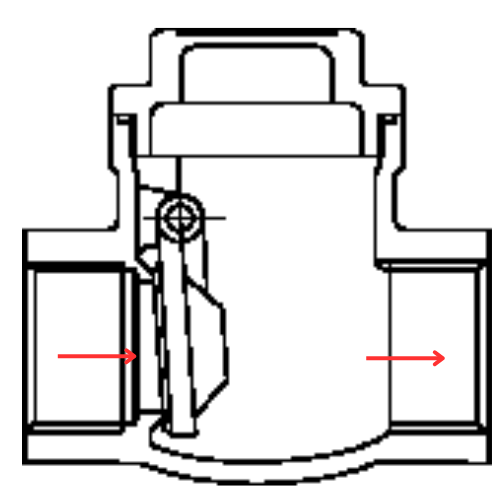

What is a Swing Check Valve? A swing check valve operates using a simple mechanism. Inside the valve is a hinged disc or flap. When fluid flows in the correct direction, it pushes the disc open and out of the flow path.

If the flow stops or reverses, the disc swings shut, either by gravity or the pressure of the reverse flow, sealing it tightly against the valve seat to stop reverse flow. These valves are needed for maintaining one-way flow in applications where reverse movement could damage pumps or compressors.

The function of a swing check valve depends entirely on the fluid flow. If the flow is forward, the fluid enters with enough pressure to lift the disc off the valve seat, allowing movement through the system.

If the flow is reversed, as soon as the pressure drops or the fluid reverses, the disc swings close, blocking any fluid from flowing back through the pipeline.

Some swing check valves are specifically designed for horizontal installation, while others, like the Y pattern swing check valve, can be used in horizontal and vertical installations (if the flow moves upward).

However, you should always follow manufacturer guidelines to ensure proper operation and health of the valve.

The T pattern swing check valve has a body shaped like a "T". The fluid flows along a straight line, while the Disc is hinged to swing out of the way, and resides in the branch section of the T.

T.

The advantages are that it is compact and easy to install/maintain.

The disadvantages are that it is not ideal for high-speed or high-flow systems, and it leads to a higher-pressure loss. The best use for T pattern swing check valves is in horizontal pipelines where there is little space.

The Y pattern swing check valve has the disc and body aligned at an angle, typically 30–45°, which allows for a smoother flow. The flow path is more gradual, which leads to minimal turbulence.

The pressure drop is lower compared to T pattern designs. The advantages are greater flow efficiency and reduced pressure loss.

The disadvantages are a larger footprint and slightly higher cost to manufacture. The best use for Y pattern swing check valves is in applications that require high flow rates and installation flexibility (horizontal or vertical).

|

Feature |

T Pattern |

Y Pattern |

|

Flow Path |

Straight |

Angled (typically 30-45°). |

|

Pressure Drop |

Higher |

Lower |

|

Flow Efficiency |

Lower |

Higher |

|

Footprint |

Lower |

Higher |

|

Cost |

Typically, lower |

Typically, higher |

|

Installation |

Horizontal only |

Horizontal or vertical |

Swing check valves are essential in a wide range of industries where backflow prevention is a must have:

Power generation

Fire protection systems

Irrigation systems

Pumping systems

These valves help protect high-value systems from damage while maintaining smooth, uninterrupted flow.

While both prevent reverse flow, they serve different purposes. A swing check valve prevents reverse flow to protect equipment. While a backflow preventer prevents contaminated water from flowing back into a clean water supply.

As mentioned earlier, a swing check valve uses a simple mechanical disc that swings open and shut. A backflow protector uses two check valves and a pressure relief valve. Backflow preventers are certified to use for clean water systems while check valves are not.

Swing check valves have a moderate level of protection that only stops reversal flow while backflow preventers have a higher level of protection that prevents siphonage, reverse pressure, and contamination.

A backflow preventer, as stated earlier, is designed to protect human health, particularly in clean water systems. While a swing check valve is focused on equipment protection and maintaining flow direction in industrial systems.

A swing check valve is just one kind of check valve, and choosing the right type depends on system requirements such as speed of closure, orientation, and fluid cleanliness. There are a variety of other types of check valves such as lift check, inline, spring loaded check, ball check, and dual plate check valves.

All these types of check valves have applications that they are best suited for and have their drawbacks. Swing check valves are ideal when simplicity and minimal maintenance are priorities.

For systems where quick closure or vertical installation is needed, other check valves may be more appropriate. Always consult your project team in helping you choose the right valve for your application.

Swing check valves play a critical role in maintaining one way flow and protecting equipment in industrial piping systems. Choosing between a T pattern and a Y pattern swing check valve depends on factors like flow speed, installation direction, space, and desired pressure drop. Understanding how these valves work can help you build more efficient and reliable systems.

Do you need help choosing the right swing check valve? Contact our sales team for more information on our inventory of valves.

EXPLORE OUR SWING CHECK VALVE OFFERING

Authors: Addison Towne, Marketing Intern and Marcus Estrella, Director of Product Line Management

Sources:

7/8/2025 8:45:06 AM